The purpose of lubricating threaded fasteners is often misunderstood. Many believe it’s simply to make removal easier, which is indeed a benefit. However, the primary reason for lubrication is to achieve consistent tightening and minimize variability caused by inconsistencies.

Correctly tightening a fastener.

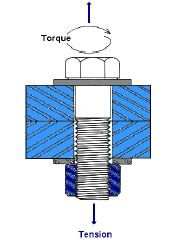

To understand why we lubricate threaded fasteners, we’ll first examine how correct tightening works. When asked, “What tool should be used to tighten a fastener properly?” most would respond, “A torque wrench.” While the torque wrench is one of the most practical ways to control fastener tension, it is crucial to understand that it does not measure tension. A torque wrench measures torque or twisting force. While that’s helpful, it can lead to problems when preloading fasteners.

A threaded fastener works by applying clamping force to the components being fastened. This is accomplished by turning the screw thread. The action of the screw thread preloads and stretches the bolt, creating bolt tension.

Clamping force

The amount of preload is critical; too much, and the bolt may exceed its elastic limit (or stretch). Too little, and the bolt may be subject to alternating forces and fatigue – something that’s all too common in threaded fasteners.

Most bolts fail due to fatigue caused by under-tightening. To be precise, when tightening a fastener, measuring the preload directly is vital. It is important to recognize that improperly measuring preload can cause serious reliability problems in mechanical systems. Fortunately, there are various methods available to ensure accurate measurement, commonly involving external tools or mathematical formulas. However, these approaches can often be complex, costly, or cumbersome, making them impractical for everyday use.

As a result, most practitioners prefer to rely on a torque wrench, but, when combined with thread lubricant, there are ways to reduce factors of variation and achieve consistency.

Consistency is key

A torque wrench can only do so much, though. When turning the bolt, some of the twisting force goes into overcoming the threads’ friction and, importantly, the nut-and-washer interface.

Even if the applied torque is meticulously controlled, many variables are at work to determine how much friction is present. These include the fastener itself, the materials, the class and type of thread, the thread condition, and many others. The result is that, despite your best efforts with the torque wrench, the clamping force applied remains inconsistent.

Inconsistency in tightening threaded fasteners can lead to under-tightening and, in turn, costly issues that can affect production time and, ultimately, profitability.

Lubricating threaded fasteners in action

It’s incredibly difficult to precisely manage clamping strength without proper thread lubrication, leading to inconsistent results and under-tightening. A hands-on exercise from Reliability Solutions’ popular Essential Craft Skills series illustrates this by comparing the performance of a dry fastener versus a lubricated bolt—and this exercise can also be performed with studs to observe similar effects—under identical tightening methods.

Each of the 15 students is asked to properly tighten a 3/8 x 16 grade 5 fastener using a standard combination wrench. Once they have tightened the bolt, the clamping force applied is then measured and recorded. For accurate results, it is important to apply lube to the threads to ensure consistent torque and bolt tension. The results are always pretty amazing.

This particular fastener is designed to apply 4940 lbs of clamping force. Classroom results varied from 6500 lbs to 1,500 lbs of clamping force!

That variation is close to 100% of the desired clamping force. Interestingly, most attempts resulted in the bolt being under-tightened by a significant amount. When bolts are under-tightened, they’ll be more likely to fail, reducing the overall reliability of the machinery they’re connected to.

When using a (calibrated) torque wrench to perform the same task, the results improved only slightly, and the scatter was reduced to 30-40% of the desired clamping. However, the numbers still varied from 6000 lbs to 4200 lbs.

Why we lubricate threaded fasteners:

This is why proper lubrication of threaded fasteners is essential: it promotes consistency. Lubrication plays a crucial role because it reduces friction between threads, which helps achieve uniform tightening and prevents damage or failure. Ensuring that fasteners are properly lubricated leads to more reliable and predictable fastening performance in various applications.

We performed the same hands-on experiment using lubricated bolts. The increase in clamp force becomes clearly noticeable when the threaded fastener is properly lubricated, reducing friction and preventing galling, resulting in a significant boost in efficiency and reliability. Additionally, the scatter was minimized to a range of 10% to 15%, which is approximately the best achievable result within the limits of torque control methods.

Words of advice from Reliability Solutions:

When tightening a fastener, the operator must always use a controlled method. Always follow the manufacturer’s recommendations regarding lubrication and torque values to ensure optimal performance and safety. Additionally, unless specifically told not to, always correctly lubricate the threaded fastener to ensure reliability and consistency. Lubricate the threads and head/washer to get consistent results. Do not use mixed lubricants unless compatibility is confirmed, as certain combinations can cause issues such as hydrogen embrittlement. Use the lubricated torque value.

For more details on calculating slip, and how to prevent it and establish manufacturing reliability, please contact Reliability Solutions